The Ultimate Guide To Roar Solutions

The Ultimate Guide To Roar Solutions

Blog Article

What Does Roar Solutions Mean?

Table of ContentsSome Known Details About Roar Solutions Roar Solutions for BeginnersRoar Solutions Fundamentals Explained

In order to safeguard installations from a possible explosion a method of analysing and classifying a possibly dangerous location is required. The function of this is to guarantee the proper option and setup of equipment to ultimately protect against an explosion and to guarantee security of life.

(https://www.anobii.com/en/01749dcc41232b575a/profile/activity)

No equipment should be installed where the surface area temperature of the devices is higher than the ignition temperature of the provided risk. Below are some usual dirt hazardous and their minimal ignition temperature level. Coal Dust 380C 225C Polythene 420C (melts) Methyl Cellulose 420C 320C Starch 460C 435C Flour 490C 340C Sugar 490C 460C Grain Dirt 510C 300C Phenolic Material 530C > 450C Aluminium 590C > 450C PVC 700C > 450C Soot 810C 570C The probability of the hazard being existing in a concentration high sufficient to trigger an ignition will certainly differ from area to place.

Dangerous location electrical devices perhaps designed for usage in greater ambient temperatures. Area Repair Service By Authorised Worker: Complex screening might not be called for however certain treatments might require to be adhered to in order for the equipment to keep its third event rating. Each piece of devices with a hazardous ranking must be assessed independently.

The Roar Solutions Statements

The equipment register is a comprehensive data source of equipment records that consists of a minimum collection of areas to determine each item's area, technological parameters, Ex classification, age, and ecological information. The proportion of Comprehensive to Close inspections will be identified by the Equipment Risk, which is evaluated based on ignition danger (the probability of a source of ignition versus the likelihood of a flammable ambience )and the harmful area classification

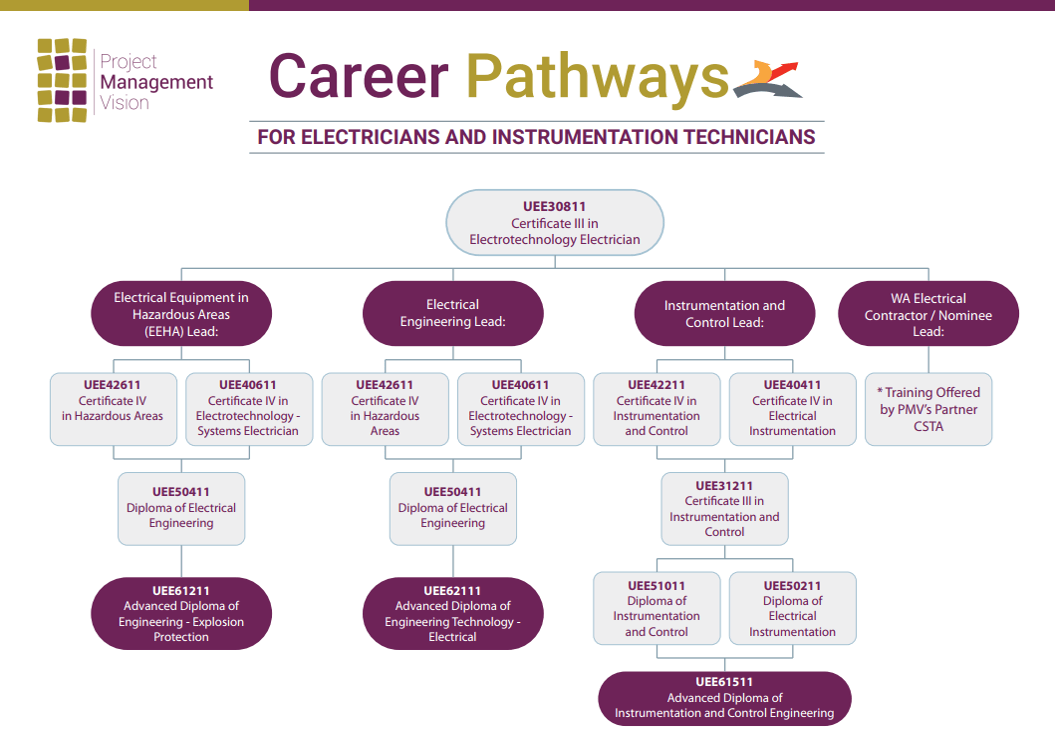

( Zone 0Area 1, or 2). Applying a durable Risk-Based Inspection( RBI )method is vital for making certain conformity and safety in taking care of Electric Equipment in Hazardous Locations( EEHA).

The 15-Second Trick For Roar Solutions

In regards to explosive threat, a harmful area is a setting in which an explosive atmosphere is present (or might be anticipated to be existing) in quantities that need unique precautions for the construction, installation and use devices. Roar Solutions. In this write-up we discover the difficulties faced in the office, the danger control actions, and the needed expertises to work safely

It is an effect of modern life that we make, keep or manage a series of gases or liquids that are considered flammable, and a variety of dusts that are deemed combustible. These compounds can, in certain problems, create explosive environments and these can have significant and tragic consequences. A lot of us are familiar with the fire triangle remove any kind of one of the 3 elements and the fire can not take place, however what does this mean in the context of unsafe areas? When breaking this down right into its most basic terms it is essentially: a combination of a particular quantity of release or leak of a certain substance or product, combining with ambient oxygen, and the presence of a source of ignition.

In many circumstances, we can do little regarding the degrees of oxygen in the air, yet we can have substantial impact on resources of ignition, for instance electric equipment. Hazardous areas are documented on the hazardous location classification drawing and are identified on-site by the triangular "EX LOVER" site link indication. Right here, amongst various other crucial details, areas are divided into three kinds depending upon the threat, the chance and period that an eruptive atmosphere will exist; Zone 0 or 20 is considered one of the most unsafe and Zone 2 or 22 is deemed the least.

Report this page